In modern manufacturing, performing surface roughness measurement close to the production line—especially for critical components like gears—has become increasingly important. Surface roughness affects not only the micro-texture of a part but also determines the smoothness, quietness, and lifespan of drivetrain systems.

In addition to roughness, waviness also plays a major role. The key difference lies in the spatial frequency ranges being evaluated. These ranges are defined in DIN EN ISO 21920 (previously DIN EN ISO 4287 and DIN EN ISO 13565) through profile-based Gaussian filters.

This raises the question:

Can a traditional coordinate measuring machine (CMM) measure roughness and waviness—and achieve results that comply with international standards?

Upgrading the CMM: From Dimensional Measurement to Surface Roughness Inspection

In recent years, CMMs have evolved far beyond simple dimensional inspection. Many systems now support optical measurement, multi-sensor integration, higher speeds, and improved accuracy—a foundation that makes surface roughness evaluation possible.

However, traditional roughness measurement systems—especially sliding block systems—come with several limitations:

How the sliding block method works

- A mechanical sliding block filters out the basic form of the surface before the stylus traces the profile.

- Because the block removes the “smooth” base profile, the CMM does not require extremely high mechanical stability or positioning accuracy.

- This allows measurement of basic roughness parameters, such as Ra and Rz.

But the limitations are significant

- The method distorts results in mid- and long-spatial-frequency ranges, making waviness evaluation (W- and P-parameters per ISO 21920) unreliable.

- Advanced parameters—such as Abbott parameters (Rv, Rp, Rk; historically ISO 13565)—cannot be evaluated correctly without complex compensations.

Conclusion:

The sliding block method is cost-effective but not suitable for accurate, standards-compliant roughness and waviness analysis.

The Solution: WENZEL’s Cantilever-Type Roughness Sensor (RS-T)

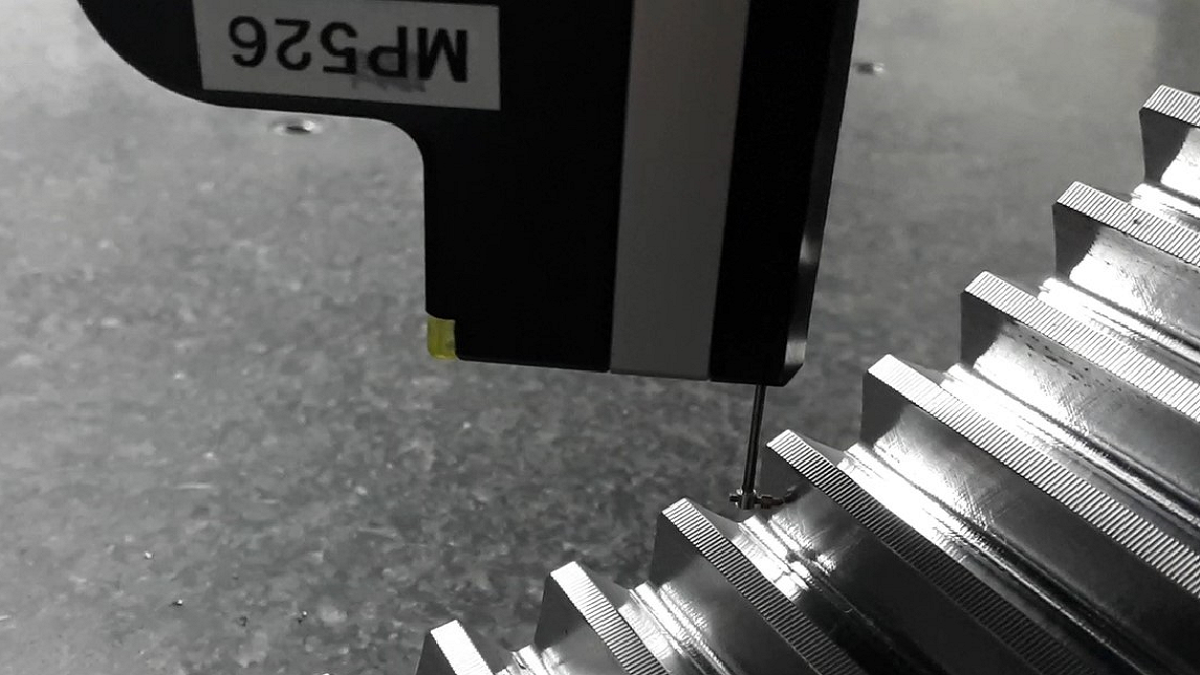

To overcome the limitations of traditional systems, WENZEL Metrology GmbH developed a cantilever-type roughness sensor—such as the WM | RS-T.

Key advantages of the RS-T sensor

- No sliding block, meaning the true profile is retained and roughness/waviness can be evaluated accurately.

- The only possible deviations come from stylus-surface interaction and the machine’s control performance.

- During measurement, the CMM remains stationary, while the sensor performs the scanning motion—ensuring stability and accuracy.

- No reference ball is used, allowing longer measurement distances and better access to complex features (e.g., small-module gears).

- The RS-T features R and T rotational axes (0°–360° and –90° to +90°), and when combined with a rotary table (C-axis) and XYZ travel, users gain six degrees of freedom—ideal for gears and complex geometries.

- RS-T behaves like a full measuring head, not just a sensor—allowing quick exchange with scanning or optical heads.

- Once calibrated correctly using a reference sphere and multiple rotational positions, the RS-T effectively transforms a CMM into a fully capable surface roughness tester, while still retaining all its dimensional measurement functions.

When Should Manufacturers Use a CMM for Roughness Measurement?

Extending roughness and waviness measurement to CMMs brings substantial benefits:

✔ Ideal for complex components

- Gears

- Precision mechanical parts

- Rotational components

- Features with complex geometry

✔ Reduces equipment requirements

A single CMM can perform geometric measurement and surface evaluation, reducing cost and saving floor space.

✔ Ensures complete quality control

Users can verify form, position, and surface texture in one integrated workflow.

✔ Suitable for high-accuracy, high-repeatability environments

Especially when waviness, tight tolerances, or automation are required.

Note: Achieving high accuracy requires:

- A high-quality cantilever sensor

- Proper calibration

- A stable, vibration-controlled CMM platform

Conclusion from Gera Hi-Tech Vietnam

Surface roughness measurement on CMMs—especially with modern sensors like the WM | RS-T—represents the future of multi-functional metrology. It allows manufacturers to elevate their quality control capabilities using a single, highly flexible device.

At Gera Hi-Tech Vietnam, we provide:

- Consultation on selecting the right CMM + roughness sensor

- Support with calibration, measurement programming, and complex surface evaluation

- Integrated metrology solutions for automated production lines

Contact our expert team for tailored advice and high-precision measurement solutions that are accurate, stable, and cost-efficient.