In industries with stringent cleanliness requirements such as electronics and semiconductors, pharmaceuticals, medical devices, and high technology, maintaining clean and contaminant-free compressed gases is a critical factor to ensure product quality and regulatory compliance.

In industries with stringent cleanliness requirements such as electronics and semiconductors, pharmaceuticals, medical devices, and high technology, maintaining clean and contaminant-free compressed gases is a critical factor to ensure product quality and regulatory compliance.

Lighthouse Worldwide Solutions (LWS) – a global leader in contamination and cleanroom monitoring – together with GERA Hi-Tech Vietnam, offers advanced solutions for compressed gas sampling and monitoring, helping manufacturers meet the most demanding international standards.

COMPREHENSIVE PARTICLE AND MICROBIAL MONITORING IN COMPRESSED GASES

🔹 Accurate Detection of the Smallest Particles

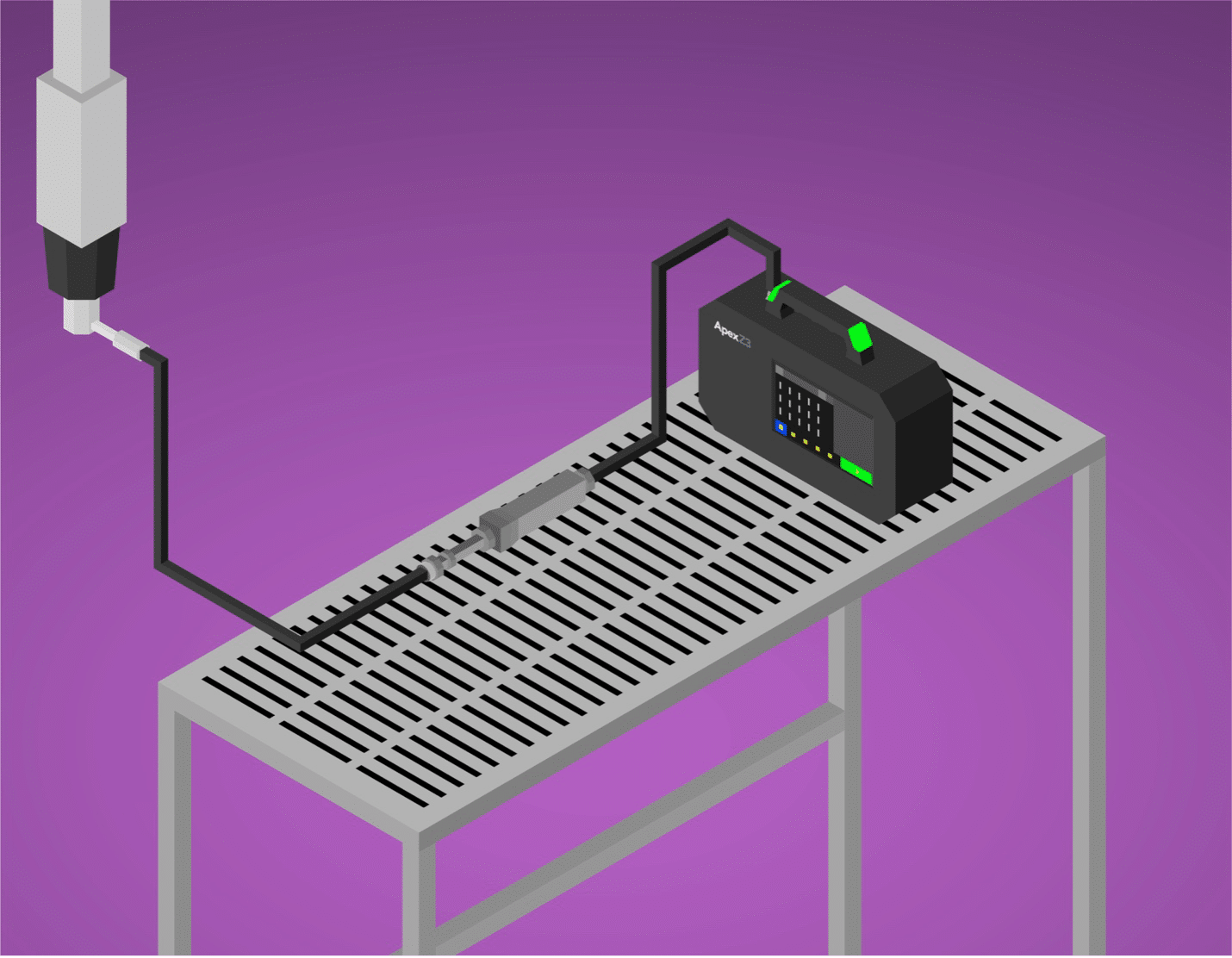

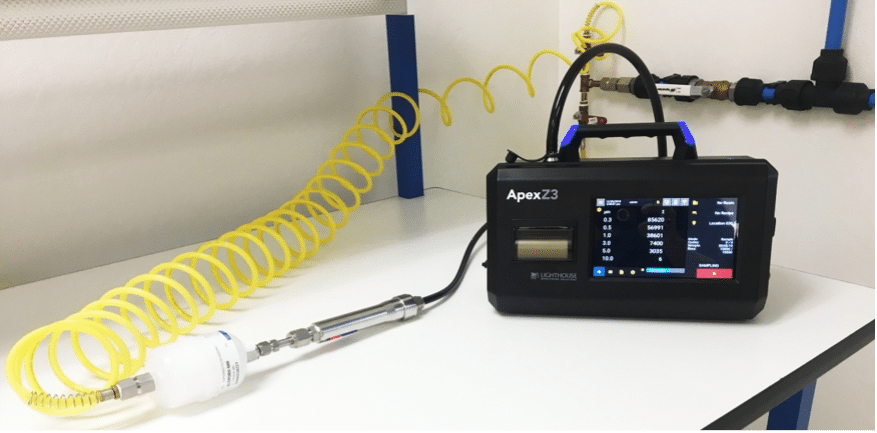

The ApexZ Airborne Particle Counter (APC) by Lighthouse is a state-of-the-art device capable of detecting particles as small as 0.3 microns.

When paired with a High-Pressure Diffuser, it enables direct sampling from high-pressure gas lines, ensuring that gases supplied to critical processes remain clean, stable, and free of contaminants.

For ultra-clean applications—such as semiconductor manufacturing, LCD production, or precision component assembly—the Solair 1100LD particle counter measures down to 0.1 microns, meeting the strictest cleanliness requirements.

🔹 Microbial Detection – Ensuring Biological Safety

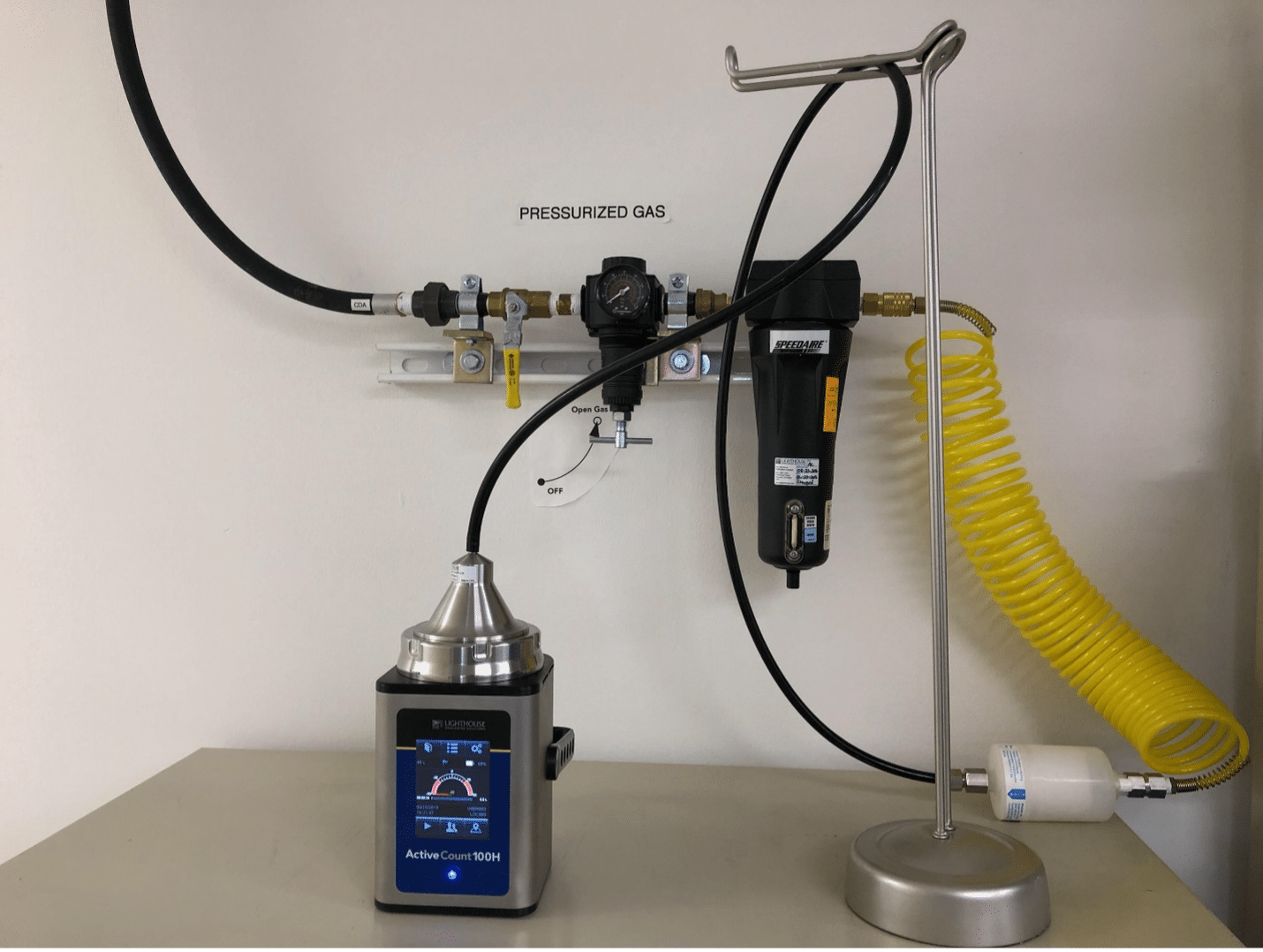

Contamination doesn’t stop at particles—microbial contamination in compressed gases is also a major concern, particularly in pharmaceutical and medical manufacturing.

Lighthouse’s active microbial samplers are designed to capture and detect live microorganisms (bacteria, molds, and fungi) present in compressed air or cleanroom environments.

Microbial monitoring is essential, especially in pharmaceutical production. Instruments such as the ActiveCount100Hare engineered to collect any microorganisms that may exist in process gases. This supports compliance with USP, EP, and cGMP regulations, which increasingly mandate microbial monitoring for gases used in cleanrooms.

COMPLIANCE WITH ISO 8573 AND GMP ANNEX 1

According to the latest GMP Annex 1 (2022) and ISO 8573 standards, all compressed gas systems supplying cleanrooms must undergo stringent testing for particles, microorganisms, water, and oil contamination.

Lighthouse’s instruments and software are designed to:

-

Provide audit-ready data with electronic signatures, audit trails, and secure data management compliant with 21 CFR Part 11.

-

Enable accurate measurement, classification, and reporting according to ISO 8573 standards.

ISO 8573 is a multi-part international standard used to classify and measure compressed air quality by defining allowable limits for three major contaminants: particles, water, and oil, at any point within a compressed air system.

It establishes standardized testing methods to ensure safety and efficiency across industrial, pharmaceutical, medical, and food production applications.

FLEXIBLE, CONNECTED, AND EASY-TO-IMPLEMENT SOLUTIONS

Lighthouse and GERA Hi-Tech’s compressed gas monitoring solutions offer:

✅ High flexibility and portability, allowing sampling at multiple points within gas supply and distribution systems.

✅ Continuous data logging and real-time alerts, easily integrated into facility monitoring systems.

✅ Comprehensive training and technical support, helping organizations develop complete contamination control programs that are compliant and effective.

WHY CHOOSE LIGHTHOUSE & GERA HI-TECH

With over 40 years of global experience in the pharmaceutical, semiconductor, and high-tech industries, Lighthouse Worldwide Solutions combines cutting-edge technology with expert consultation to help you establish a reliable, repeatable, and compliant contamination control program.

Their solutions help minimize recall costs, production downtime, and risks to patient safety or product integrity.

In Vietnam, GERA Hi-Tech is committed to delivering:

-

Advanced monitoring technologies – genuine products imported directly from LWS.

-

Full lifecycle support – from calibration and sampling to system maintenance.

-

Expert consultation to help manufacturers optimize processes, reduce risk, and ensure full regulatory compliance.

📞 Contact GERA Hi-Tech Vietnam today for detailed consultation on compressed gas monitoring solutions and on-site calibration or sampling services in accordance with ISO 8573 and GMP Annex 1 standards.