In pharmaceutical, semiconductor, and medical device manufacturing, airborne particle monitoring plays a critical role in maintaining GMP compliance, meeting ISO cleanroom classifications, and minimizing cross-contamination risks.

One of the most advanced and reliable solutions trusted by leading manufacturers today is the Remote Particle Counter (RPC) — an automated 24/7 monitoring technology from Lighthouse Worldwide Solutions, officially distributed and technically supported in Vietnam by GERA Hi-Tech.

What Is a Remote Particle Counter?

Unlike portable counters that must be manually moved between locations, remote particle counters are permanently installed at key points inside cleanrooms.

These devices operate continuously 24/7, measuring the number and size of airborne particles in real time. This enables early detection of contamination events that manual sampling could easily miss.

Each system integrates seamlessly with Environmental Monitoring Software (EMS) to automatically trigger alerts when particle concentrations exceed defined limits — ensuring accurate, consistent, and regulatory-compliant data.

How It Works

Remote particle counters detect particles using laser light scattering technology.

When particles pass through the laser beam, light is scattered and converted by a photodetector into an electrical signal proportional to particle size and count.

Depending on your facility’s setup, you can choose between:

-

Built-in pump models (ApexRp Series): Independent operation without a central vacuum system — ideal for facilities requiring flexible installation.

-

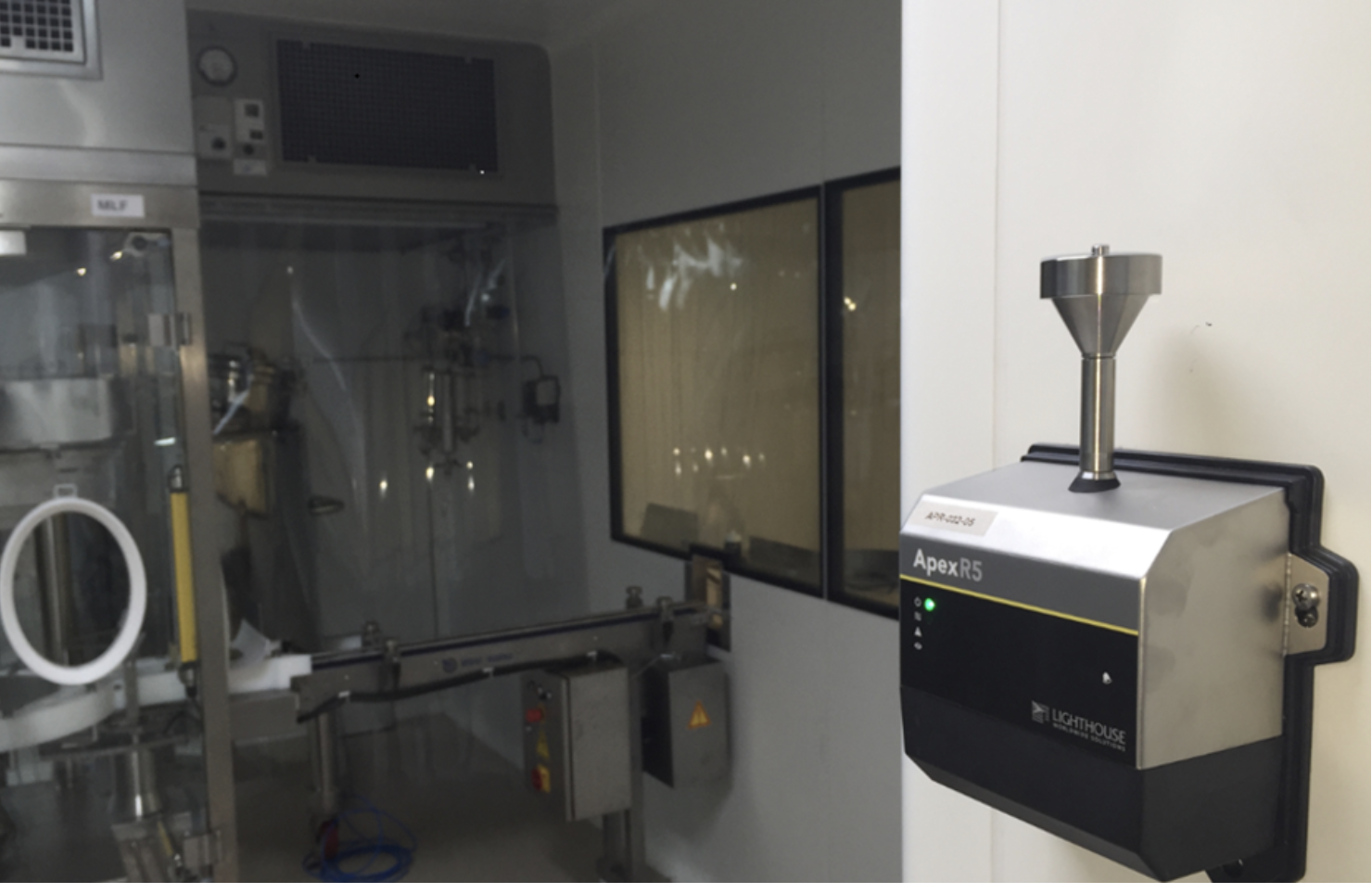

Vacuum-connected models (ApexR Series): Compact, quiet units that connect to your existing vacuum infrastructure — perfect for facilities with a stable central vacuum line.

Key Benefits of Remote Particle Monitoring

1️⃣ Real-Time Monitoring — Instant Contamination Detection

Continuous measurement captures short-term contamination spikes that daily manual checks often miss, ensuring compliance in ISO Class 5 sterile zones.

2️⃣ Reduced Human Error

Fixed-position devices eliminate the need for manual handling, reducing the risk of cross-contamination and airflow disruption in sensitive environments.

3️⃣ Automated Alerts & Centralized Data

The system sends real-time alerts when limits are exceeded and automatically logs data to BMS, LIMS, or EMS platforms, supporting traceability and audit readiness.

4️⃣ Global Regulatory Compliance

Continuous airborne particle monitoring has been required in aseptic areas (ISO 5) for over 20 years and remains the gold standard for environmental control and data integrity.

Smart Features for Accuracy & Reliability

Modern remote particle counters like the ApexR and ApexRp offer built-in self-diagnostics, alerting operators to potential issues such as:

-

Laser degradation or signal errors

-

Vacuum pressure anomalies or data interruptions

This ensures uninterrupted, accurate measurements and proactive maintenance to maintain compliance and data integrity.

SmartBracket™ — Intelligent Mounting for Data Integrity

Accurate data starts with proper installation.

The SmartBracket™ system by Lighthouse is purpose-built for cleanrooms, ensuring:

-

Fixed and accurate positioning — preventing location errors during maintenance.

-

Integrated ID chip for exact device mapping within the monitoring network.

-

Seamless cable and vacuum line concealment for a clean, hygienic, and watertight setup.

Three Flexible Mounting Options

-

Direct Mount:

Vacuum tubing and CAT6 cables connect directly to the ApexR unit. -

Floor-Directed Cable Management:

Ideal for downward cable routing, preventing cable stress or bending. -

In-Wall Installation:

Fully concealed cabling for space efficiency and easy cleanroom maintenance.

Why Choose GERA Hi-Tech Vietnam?

As the official distributor of Lighthouse Worldwide Solutions in Vietnam,

GERA Hi-Tech provides a complete cleanroom monitoring solution, including:

-

End-to-end services: consulting, installation, calibration, maintenance, and training

-

Experienced engineering team with deep knowledge in pharmaceutical, semiconductor, and high-tech manufacturing processes

-

Local after-sales support meeting international standards

Contact GERA Hi-Tech Vietnam today to learn more about:

-

ApexR / ApexRp Remote Particle Counter Systems

-

Cleanroom monitoring, sampling, and calibration services (ISO/IEC 17025:2017 certified)